Overview

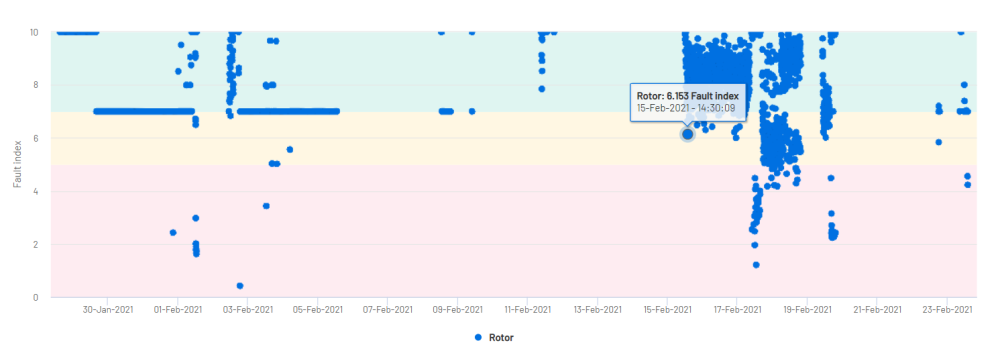

After an ADI OtoSense™ Smart Motor Sensor (SMS) device is attached to a motor, the device begins transmitting data from its on-board sensors to the ADI OtoSense™ Cloud. At regular intervals, the SMS device sends a 2.4 second sample of all sensor data (see Figure 1).

During an initial learning period, the Smart Motor Sensor works alongside the ADI OtoSense™ Cloud to create a uniquely tailored baseline model of a motor’s operation.

Once the learning period has finished, the ADI OtoSense™ Cloud is able to detect motor performance anomalies and generate alerts about impending motor issues.

Figure 1: The ADI OtoSense™ Smart Motor Sensor Communicating with the ADI OtoSense™ Cloud

About the learning period

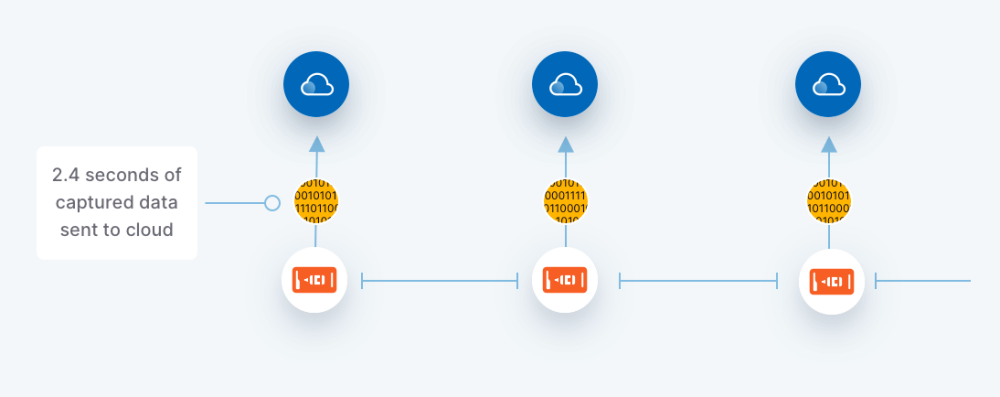

At regular intervals, the SMS device sends 2.4 second samples of sensor data to the ADI OtoSense™ Cloud. A proprietary algorithm extracts the most useful parameters for analytics purposes and generates a baseline model tailored to each motor’s operation (see Figure 2).

Figure 2: The Learning Period

Normal operation mode

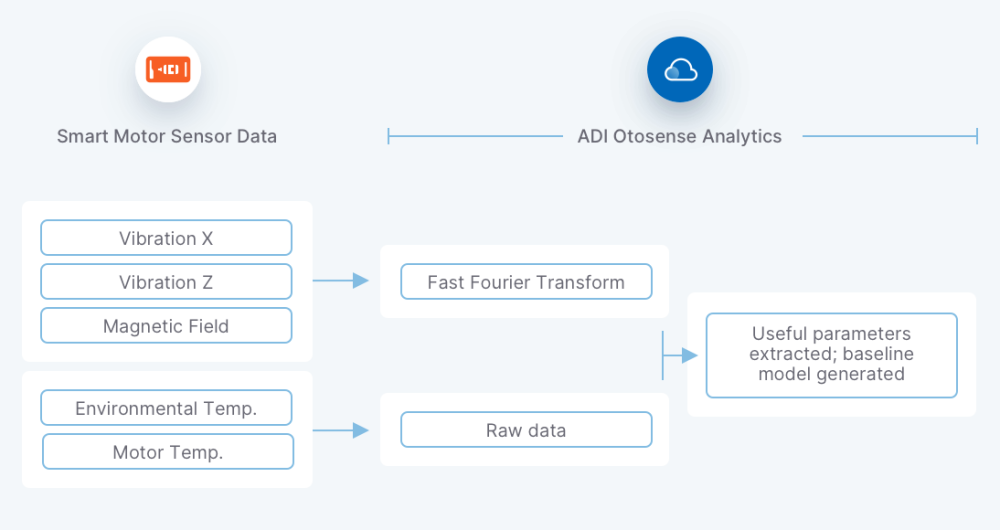

Once the learning phase has finished, the ADI OtoSense™ Cloud platform compares incoming sensor data to the baseline model to detect impending motor failures (see Figure 3). Status updates regarding ten key motor attributes (see Motor condition monitoring) as well as raw and processed sensor data (see Appendix A) are available via the ADI OtoSense™ SMS Cloud dashboard, the ADI OtoSense™ SMS mobile application, and the ADI OtoSense™ SMS API.

Figure 3: Normal Operation Mode

Motor condition monitoring

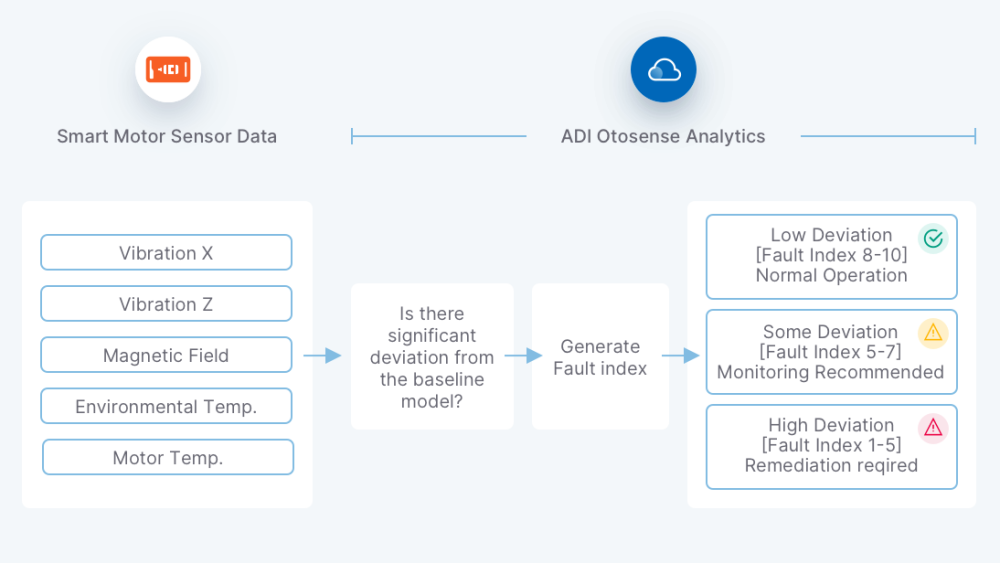

Based on incoming sensor data, ADI OtoSense™ Cloud analytics provides insight into 9 motor attributes as well as overall motor performance (see Table 1). Motor condition status is rated on a 1-10 scale, wherein ‘10’ indicates normal operation, ‘5’ indicates that monitoring is recommended, and ‘1’ indicates imminent motor failure (see Figure 4, Figure 5, Figure 6, and Figure 7). Motor attribute insights are accessible via the ADI OtoSense™ Cloud Dashboard, the ADI OtoSense™ SMS mobile application, and ADI OtoSense™ SMS API.

Table 1: Motor Attributes Monitored by the ADI OtoSense™ Cloud Platform

| Motor Attribute | Type | Description | Example Problem | |

|

Power System | Electrical | Problems in the three phases of the power supply, which could lead to a motor current imbalance. | Lost phase |

|

Stator Winding | Electrical | Problems in one of the phases of the motor, which could cause an imbalance of the motor currents. | Coil short circuit |

|

Rotor | Electrical | Short-circuit ring or rotor bar related problems. | Broken rotor bar |

|

Motor Shaft / Balance | Electromechanical | Unequal distribution of mass, causing the center of gravity to shift from the center of rotation. | Rotor flexion |

|

Eccentricity | Mechanical | Asymmetric air gap between the rotor and stator. | Bent shaft; improper bearing installation |

|

Bearing | Mechanical | Mechanical stress or contamination leading to small cracks or defects that occur in the bearing, creating vibration problems. | Pitting |

|

Alignment | Mechanical | Occurs when two rotating shafts (motor and load) are not aligned, creating external misalignment. | Angular or parallel misalignment |

|

Cooling System | Temperature | Problems with fans attached to the shaft or externally attached to the motor. | Fan cover collapse |

|

Loose Foot | Mechanical | Structural looseness occuring when the motor base (or connection to the motor base) is not properly tightened. | Motor not fixed to base frame |

|

Performance | N/A | Used to capture abnormal events such as an overall increase in vibrations, unusual changes in motor RPM, motor load or temperatures, etc. Indicates faults that do not correspond to any of the other nine fault categories, which could be related to machine process. | N/A |

Figure 4: Stator Winding Fault Index 10 on the ADI OtoSense™ Cloud Dashboard

Figure 5: Loose Foot Fault Index 5 on the ADI OtoSense™ Cloud Dashboard

Figure 6: Power System Fault Index 2 and Suggested Remediation Action on the ADI OtoSense™ Cloud Dashboard

Figure 7: Rotor Fault Index Historical Data on the ADI OtoSense™ Cloud Dashboard